Failure Analysis and Integrity Management

Failure analysis and integrity management of pipeline, piping and equipment is one of CCPGE’s areas of expertise. Failure analysis includes finite element analysis (FEA) of stress and deformation, fatigue and material fracture characterization for structures subjected to static and/or dynamic loads in a working environment. This provides technical reference for finding root causes for mechanical failure and also for improving the design of equipment, piping and structures. CCPGE has a successful track record for failure analysis and integrity management projects, and has also published numerous technical papers in international journals and conferences. The main software tools used in CCPGE include AutoPIPE, CAESAR II, ANSYS and ABQUS.

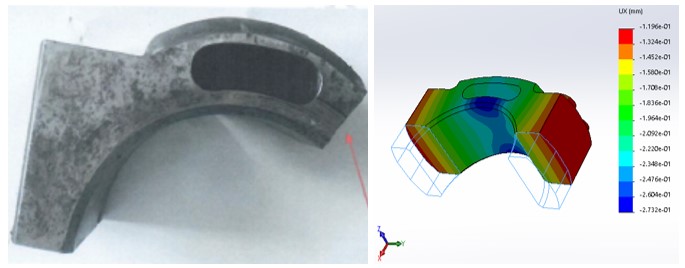

Failure Analysis and Design Improvement of Connection Rod Cap

Failure Analysis and Design Improvement of Cylinder Body

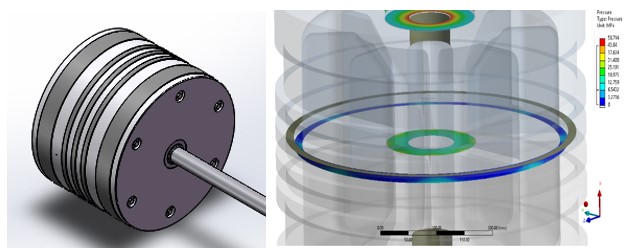

Failure Analysis and Design Improvement of Piston Assembly

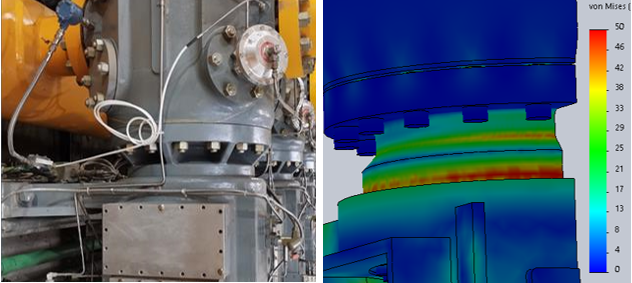

Failure Analysis and Design Improvement of Cylinder Joint Structure

Pipeline integrity management is one of the main areas of development at CCPGE. As Dr. Duan, CCPGE’s pipeline integrity expert, pointed out at CIPC 2021 in Beijing, pipeline integrity management should be more than just a fitness-for-service assessment and repairs during the pipeline’s operating stage: It must be a management strategy that applies throughout the pipeline’s service life cycle, beginning with the design stage, through construction and operation, all the way to decommissioning. At CCPGE, for integrity management, we help implement code requirements and more detailed, company-specific procedural requirements.

Pipeline integrity assessment involves various technical aspects including pipeline stress/strain design methodology, material qualification, girth weld quality, corrosion, and environmental stress cracking.

Pipe stress /strain based design

Typical stress-based design of pipelines does not properly consider ground conditions that may cause pipe uplift and pipe floating in muskeg areas, as well as pipe-soil interactions and soil ratcheting. These problems can be resolved effectively by partially introducing strain-based design methodology.

Pipe Arches and Lifts Out of the Ground

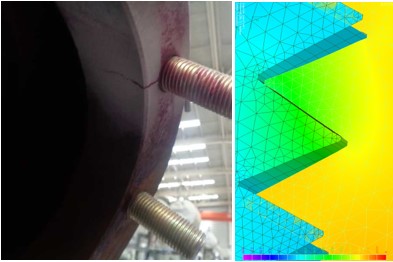

Girth Weld Failure

Girth weld quality

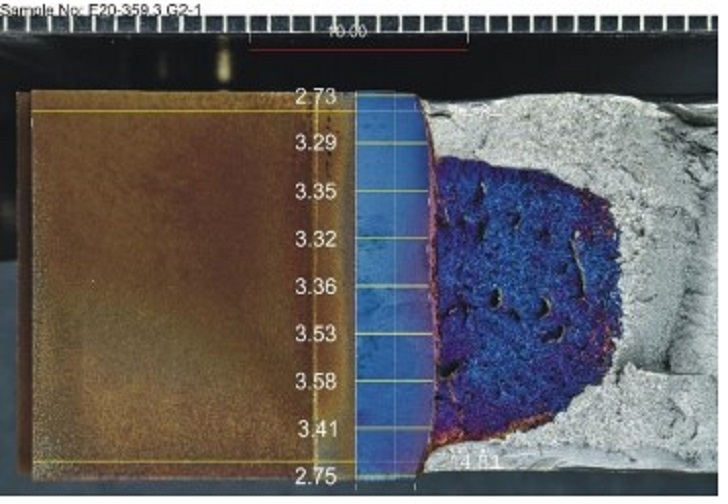

Fracture failure in girth welds has become a major threat to pipeline integrity. Weld overmatching requirements have recently been receiving more attention due to frequent field failures. For girth welding, workmanship acceptance criteria do not guarantee the quality of welds in terms of structural safety. Based on fracture mechanics, engineering critical assessment (ECA) provides a better way for accepting welds for applications in various working conditions. At CCPGE, we have well recognized industry experts for ECA and its field implementation. We have completed numerous pipeline ECA projects in collaboration with other well recognized US companies.

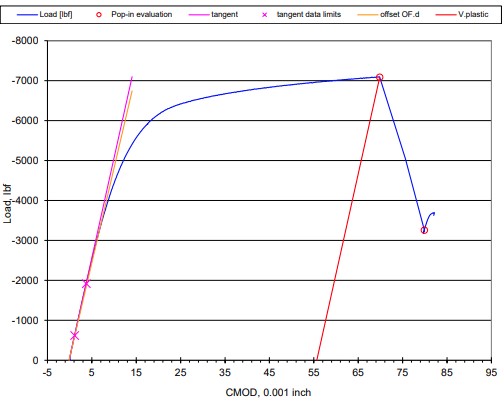

Fracture Toughness Test

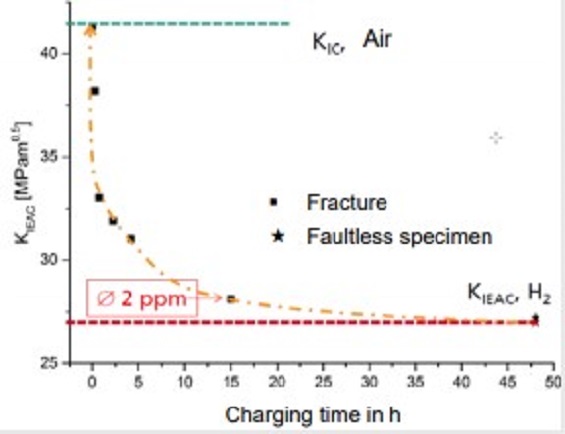

Environmental stress cracking and hydrogen pipelines

The current integrity assessment is mainly based on traditional fracture mechanics. For hydrogen pipelines, the assessment philosophy based on traditional fracture mechanics is no longer applicable. Some preliminary experimental results indicated that the fracture behavior of hydrogen pipeline materials is different from common pipeline materials. For example, Multiple fracture toughness values have been found which makes the current fracture criterion K

Multiple Fracture Toughness

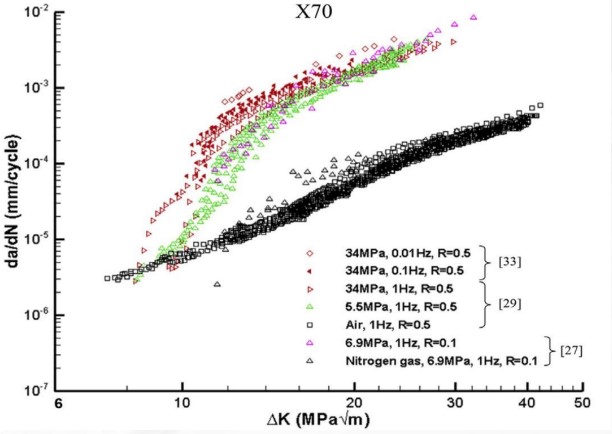

Progress of Fatigue Crack Depends on Loading Frequency

CCPGE has been working with industry partners in various areas of pipelines transporting hydrogen and hydrogen/natural gas blends. These include gas pipeline repurposing, material testing in hydrogen and slow crack growth characterizations and predictions.

![[PNG] _ccpge-logo-wide-black](http://www.ccpge.com/wp-content/uploads/2023/09/PNG-_ccpge-logo-wide-black.png)