Piping Vibration Risk Assessment

Piping Vibration Risk Assessment is a core component of CCPGE’s business. Piping vibration can be caused by multiple factors, including Flow Induced Turbulence (FIT), Flow Induced Pulsation (FIP), Acoustic Induced Vibration (AIV), Small Bore Connection (SBC), etc. The purpose of vibration risk assessment is to reduce the risk of piping vibration failure.

CCPGE uses VibTech quantitative assessment tools, together with Bentley PULS and AutoPIPE software, to conduct piping vibration risk assessment in accordance with the Energy Institute Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework, second edition (2008)

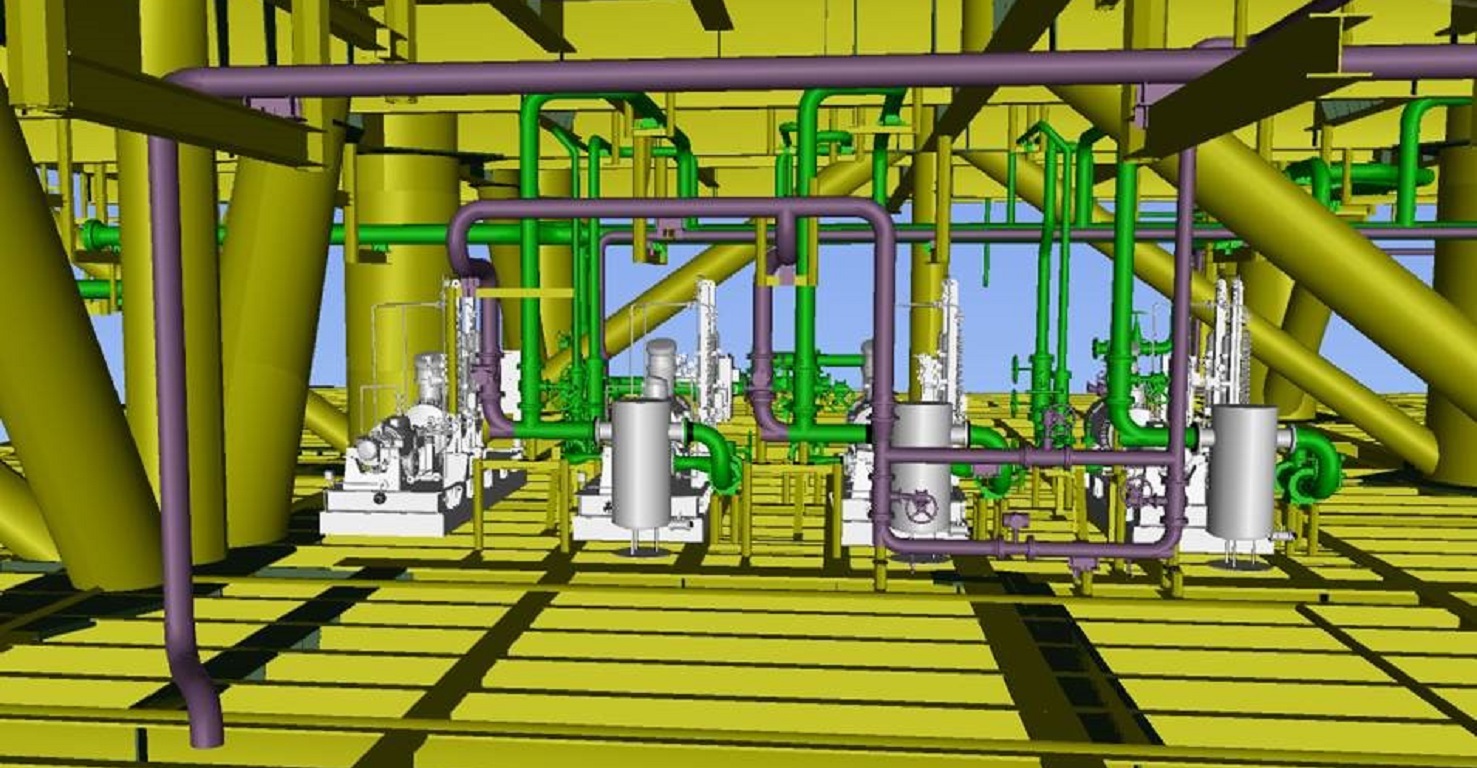

Below is an off-shore platform piping system which had undergone piping vibration risk assessment (FIT, FIP, AIV, and SBC, etc.) at the design stage by CCPGE for the purpose of improving the reliability of piping system design.

Lufeng Off-shore Platform Piping System

Flow Induced Turbulence

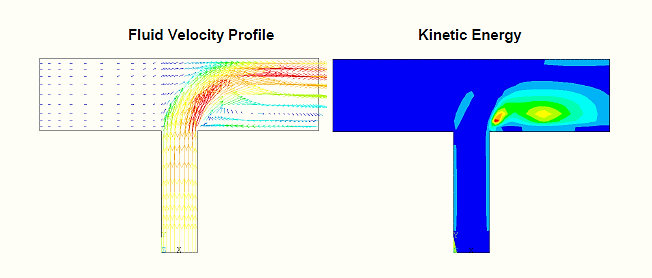

Flow Induced Turbulence (FIT) exists at the turbulent boundary layer at the pipe wall in straight sections, as well as at major flow discontinuities in the system such as bends, partially closed valves, tees, and reducers. The excitation energy that causes flow induced turbulence comes from the kinetic energy of the flowing fluid, which is dependent partially upon the speed and density of the fluid. This kinetic energy results in low frequency (below 100 Hz) excitation energy, which, if it coincides with the natural mechanical frequencies of the pipe, can result in high levels of vibration.

FIT at a Tee (Cited from EI Guideline 2008)

FIT Assessment Results

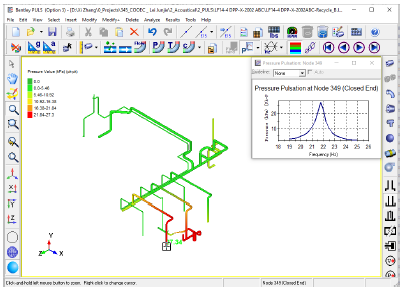

Flow Induced Pulsation

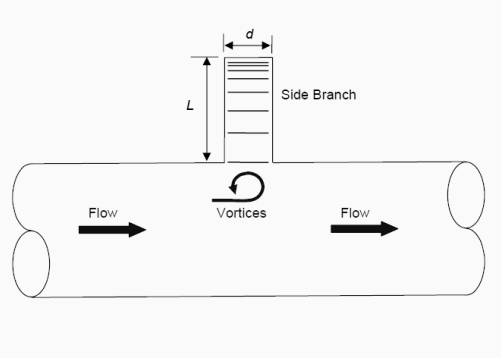

Flow Induced Pulsation (FIP) is caused by flow past a closed side-branch in a piping system, which creates vortices to be shed at specific frequencies. If these vortex shedding frequencies coincide with the acoustic natural frequency of the side-branch, amplification of the vibration can occur. The pulsation generation mechanism is outlined in the figures below.

FIP at a Closed Side-Branch (Cited from EI Guideline 2008)

FIP Pulsation Study Model

Acoustic Induced Vibration

Acoustic Induced Vibration (AIV) are high frequency excitations (generally 500 Hz to 2000 Hz) that are generated by pressure reducing devices such as relief valves, control valves and orifice plates. AIV in gas systems causes shell mode vibration and can lead to rapid failure (within hours) as well as excessive noise concerns.

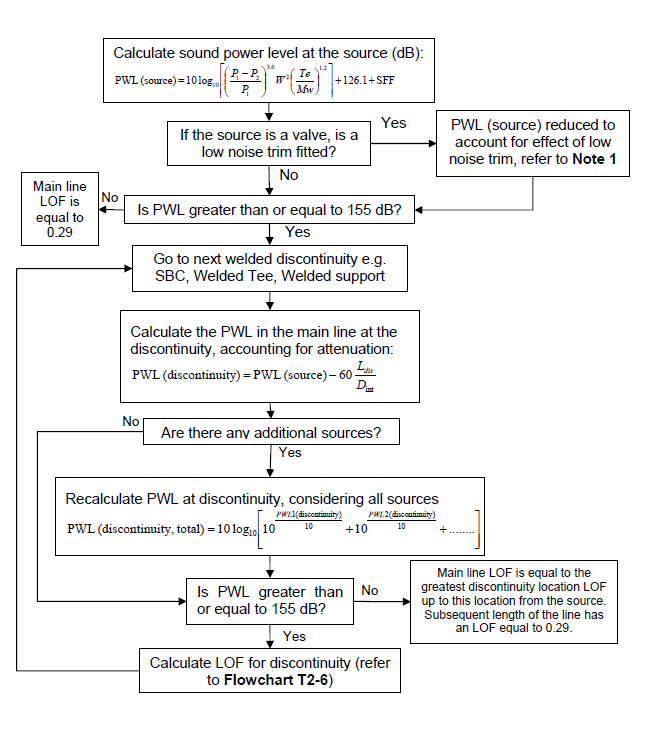

AIV Assessment Flowchart I (Cited from EI Guideline 2008)

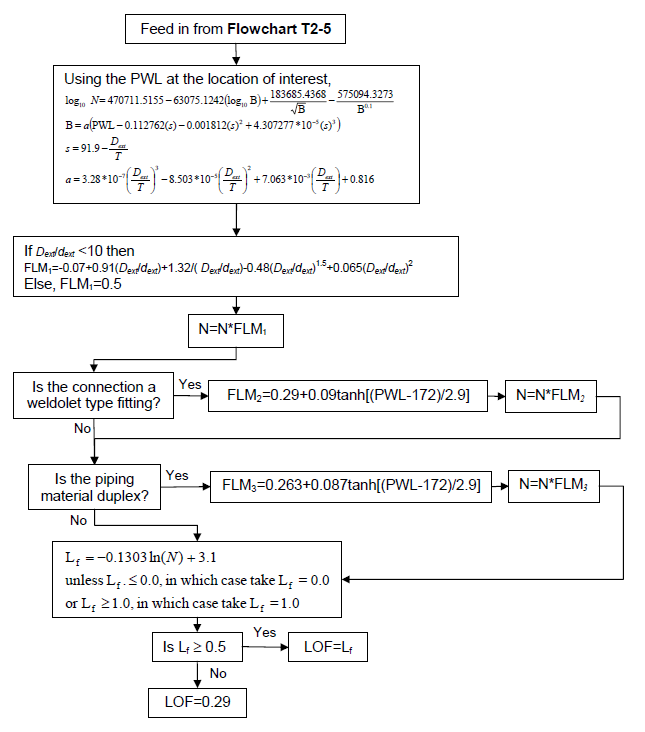

AIV Assessment Flowchart II (Cited from EI Guideline 2008)

Small Bore Connection Assessment

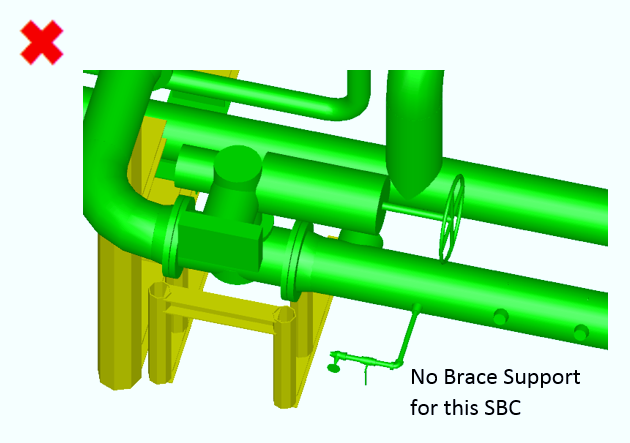

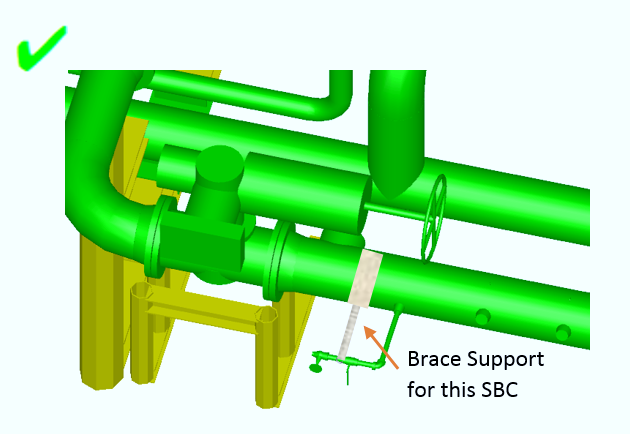

Small Bore Connection (SBC) Assessment is performed to assess the effects of each excitation source on small bore connections (less than NPS 2”) on the main line. SBCs are especially susceptible to vibration issues and are often inadequately supported and poorly designed, meaning these connections often have a risk of vibration even if the main line is adequately supported.

The goal of SBC assessment is to identify poorly designed and supported SBCs and improve their design, including bracing them to the main pipe securely and reducing the length of SBC as much as possible.

SBC without Brace Support

SBC with Brace Support

![[PNG] _ccpge-logo-wide-black](http://www.ccpge.com/wp-content/uploads/2023/09/PNG-_ccpge-logo-wide-black.png)