Pipeline and Piping Stress Analysis

Pipeline and piping stress analysis is one of the most common business activities of CCPGE. Most of our engineers have significant hands-on professional experience participating in or leading large-scale EPCM pipeline and piping stress analysis projects before joining CCPGE.

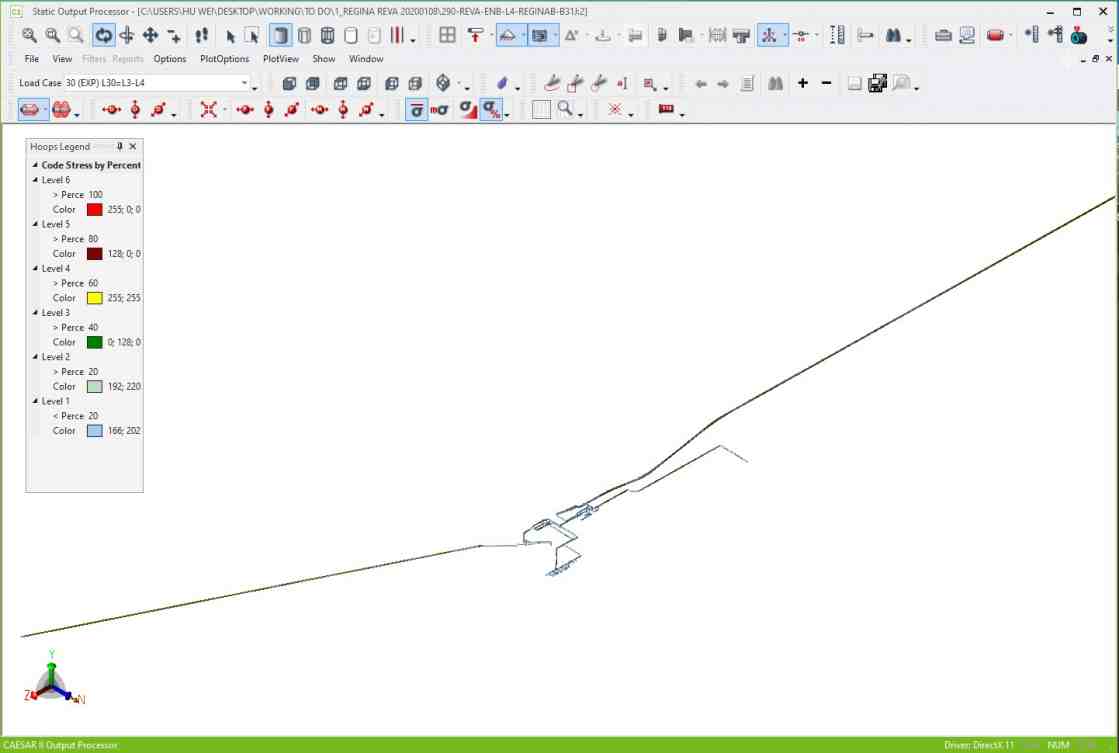

Pipeline stress analysis includes pipe wall thickness calculations, soil spring stiffness calculations, buoyance control calculations, code stress and deflection calculations, global and local buckling checks, road crossing fatigue stress calculations, lowering-in stress calculations, pipe support design and support loads calculations, and other analysis. CCPGE performs these analyses in compliance with CSA Z662, B31.4 and B31.8, with the application of B31J when needed. The loads of pipe weight, earth dead load, pressure, temperature, hydro-test, settlement, blow-down, and seismic loads, etc. are all taken into account.

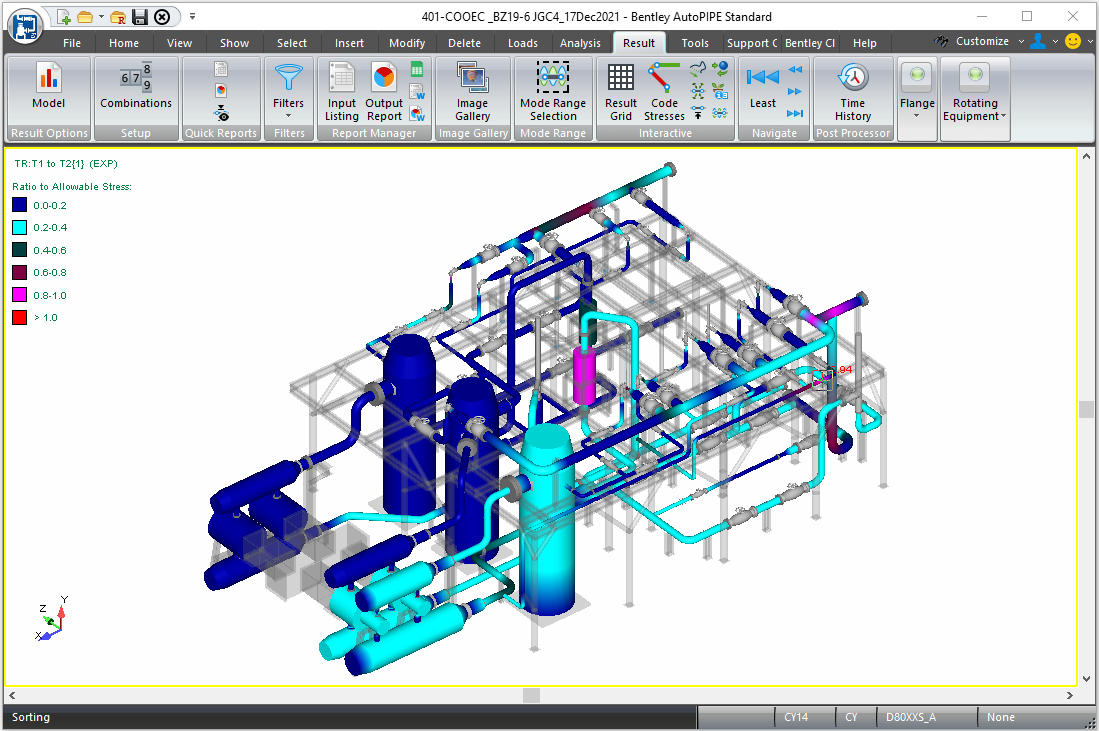

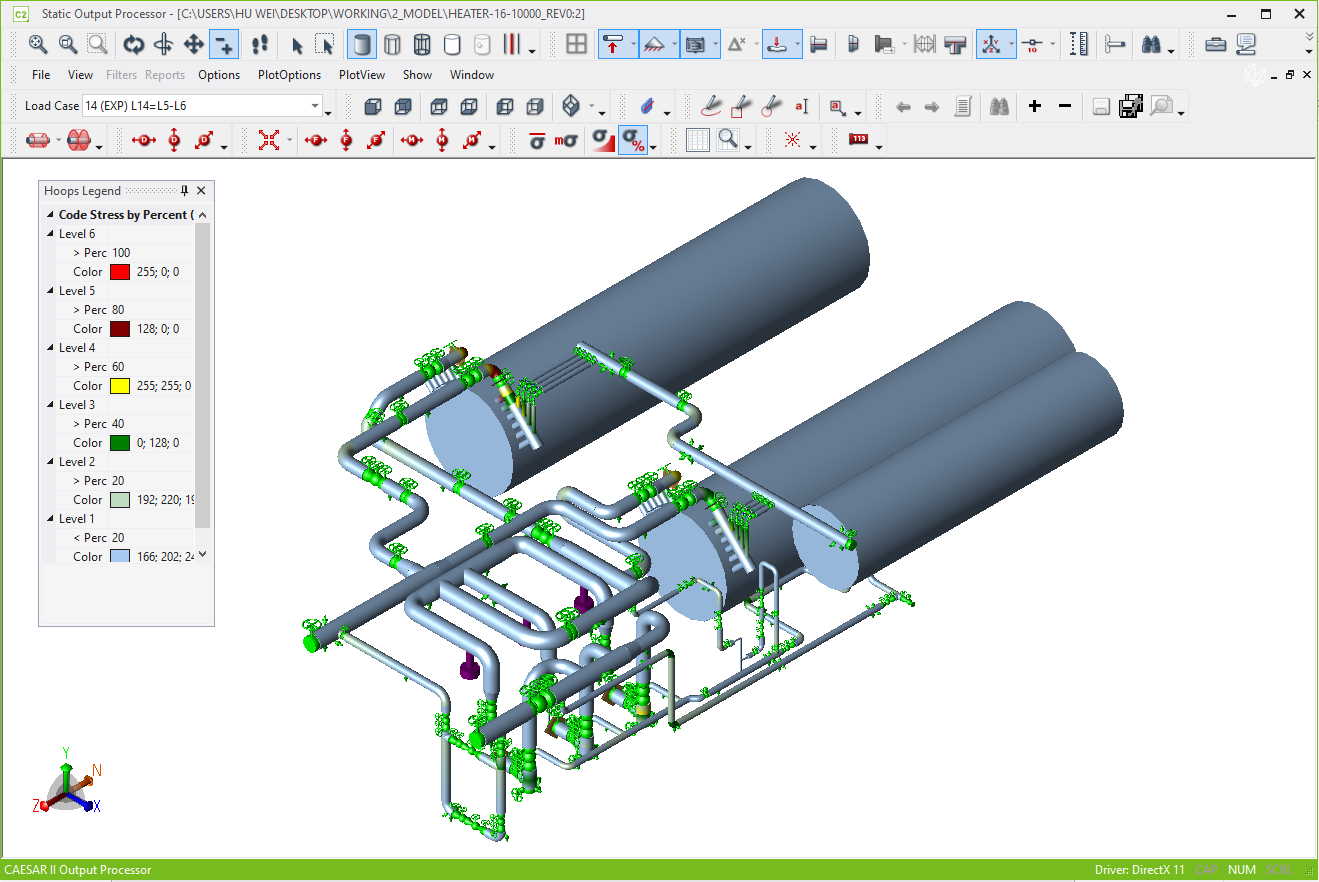

Piping stress analysis includes pipe wall thickness calculations, local stress calculations, code stress and deflection calculations, flange leakage checks, pressure vessel and equipment (turbine, pump, compressor, cooler, etc.) nozzle load checks, pipe support design and support load calculations, and any other applicable analysis. This is done in compliance with CSA Z662, B31.3 and B31.1. The loads of pipe weight, pressure, temperature, hydro-test, settlement, wind load, snow load, PSV load, two-phase flow load, seismic loads, etc. are all taken into account.

Stress Analysis of a Compressor Station Piping System

Stress Analysis of an Offshore Compressor Package Piping System

Stress analysis of a Hot Oil Heater Package Piping System

Stress Analysis of Pump Station and Connected Under Ground Pipeline

![[PNG] _ccpge-logo-wide-black](http://www.ccpge.com/wp-content/uploads/2023/09/PNG-_ccpge-logo-wide-black.png)