Pulsation and Mechanical Analysis

Pulsation (acoustical) and mechanical analysis of reciprocating compressor /pump packages is the core business activity of CCPGE. The purpose of pulsation (acoustical) and mechanical analysis is to reduce gas pressure pulsation in the piping system, thereby avoiding reciprocating compressor /pump operation complications in terms of vibration, insufficient performance, poor reliability, flow measurement errors, etc.

Due to the intermittent gas flow through the reciprocating compressor /pump suction and discharge, pressure fluctuation, i.e. gas pressure pulsation, occurs in reciprocating compressor /pump piping system. As a result, compressor /pump operation problems can arise, namely unacceptable shaking force and piping vibration, high system power consumption and energy loss, intake and discharge valve damage, and flow measurement errors, etc.

API 618 (5th edition, December 2007) and API 674, published by the American Petroleum Institute, present pulsation and mechanical analysis approaches for reciprocating compressor /pump packages, respectively. While API 674 provides 2 design approaches: Design Approach 1 (DA1) and Design Approach 2 (DA2), API 618 presents 3 design approaches: Design Approach 1 (DA1), Design Approach 2 (DA2), and Design Approach 3 (DA3) (note that API 618 DA1 is not the same as API 674 DA1, and similarly for DA2). The 3 design approaches used for reciprocating compressor packages are applicable for different cases as detailed in the table below:

API 618 Design Approach Selection

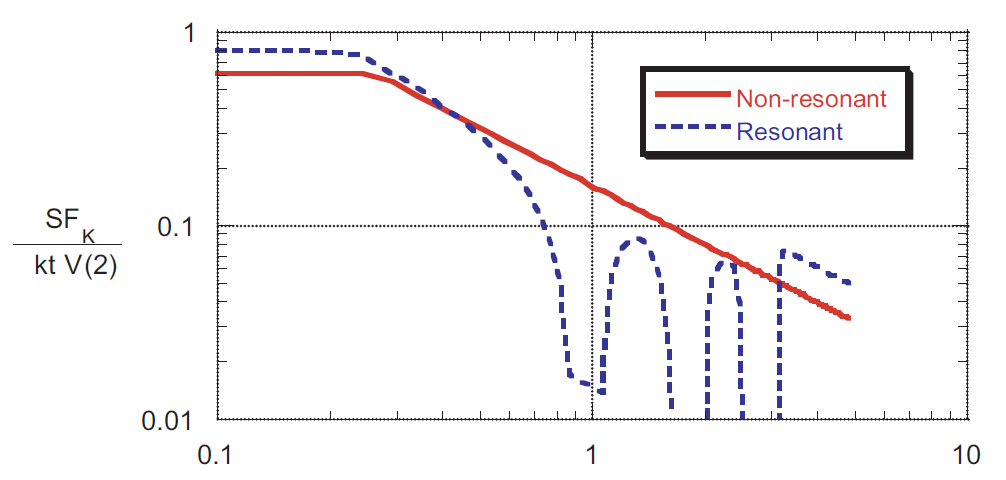

API 618 Non-dimensional Pulsation Suppression Devices Shaking Force Guideline

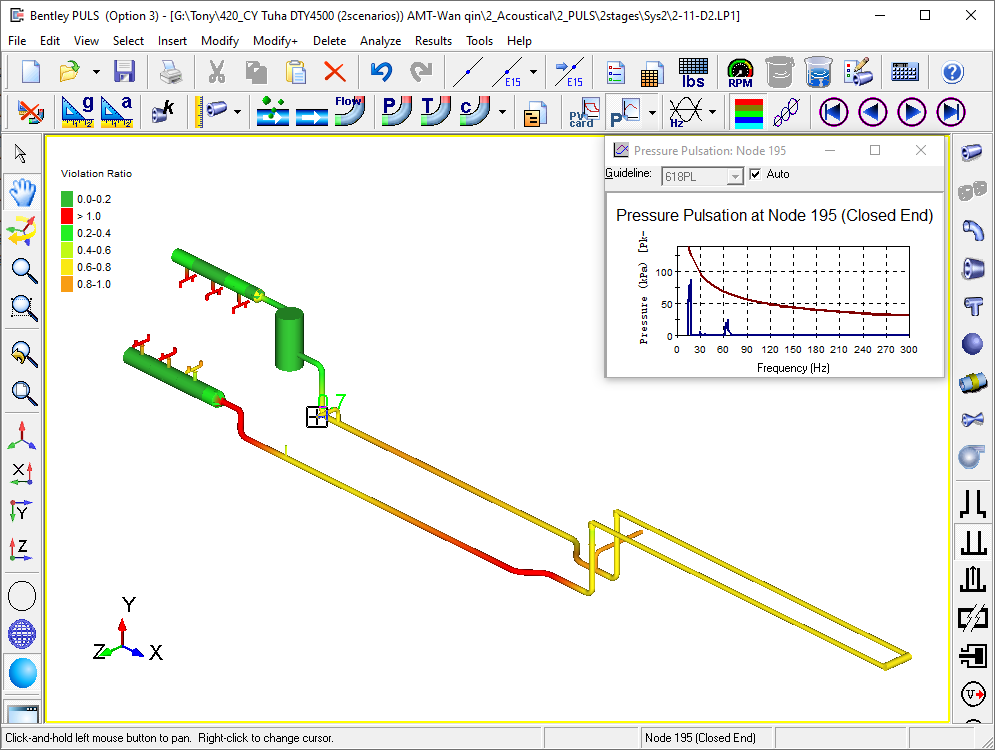

Bentley PULS XM is one of the most recognized software in the industry for pulsation (acoustical) study per API 618 and API 674 standards. It was initially developed by NOVA-HUSKY research institute in Calgary, Canada, and then improved upon by the SSD engineering consulting firm, Bentley and other companies. It is currently an effective acoustical study tool.

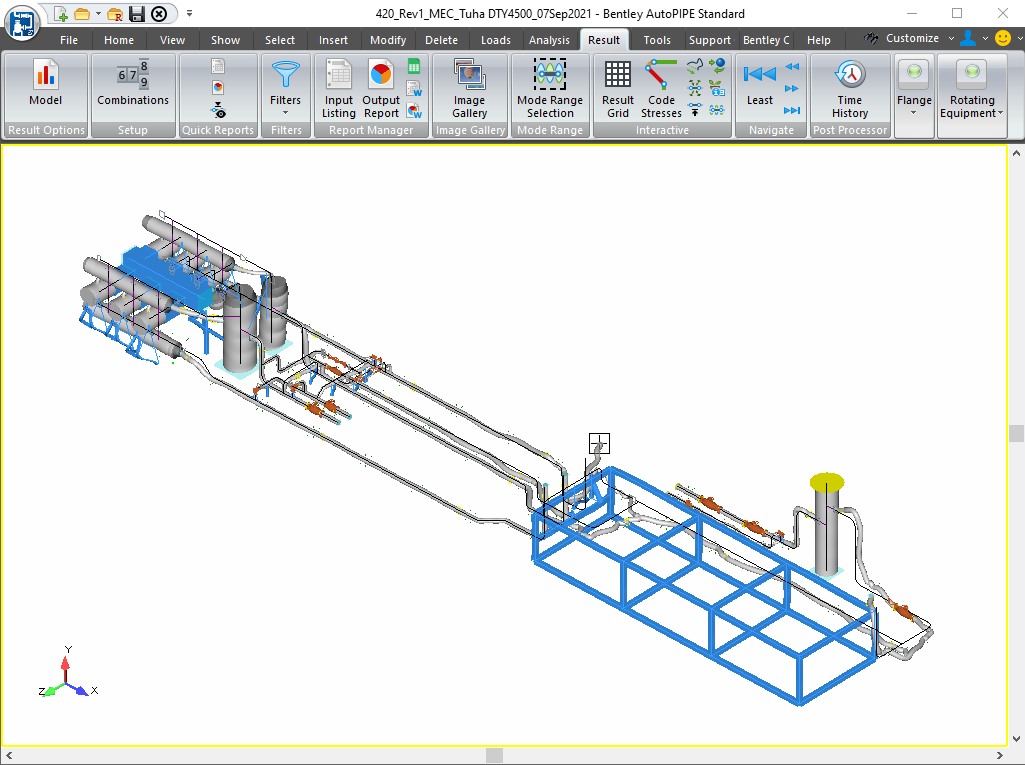

Mechanical analysis is an important part of Design Approach 3 (DA3) in API 618. The purpose of mechanical analysis is to adjust the piping layout and support design to avoid mechanical resonance of compressor manifold and piping systems, and thus limiting the vibration level and dynamic stress of compressor /pump package components within the allowable range.

Bentley AutoPIPE CONNECT is a widely used piece of software globally for mechanical analysis. It’s user-friendly interface seamlessly integrates with Bentley PULS XM, allowing smooth and efficient model data exchange.

CCPGE uses Bentley PULS XM and Bentley AutoPIPE CONNECT software to perform acoustical and mechanical analysis of reciprocating compressor /pump packages per API 618 design approaches and API 674 Standard.

Pulsation (Acoustical) Study Model of an Inter-stage System in a Gas Storage Compressor Package

Mechanical Analysis Model of a Gas Storage Compressor Package

![[PNG] _ccpge-logo-wide-black](http://www.ccpge.com/wp-content/uploads/2023/09/PNG-_ccpge-logo-wide-black.png)