Pressure Vessel Design and Analysis

Fatigue stress analysis and design of pressure vessels are key aspects of CCPGE’s business. The purpose of this analysis is to evaluate whether or not the pressure vessel design meets the requirements of ASME VIII Div 1&2 and/or other specified standards.

At CCPGE, Finite Element Analysis (FEA) using ANSYS is employed to analyze pressure vessels where the configuration of the pressure vessels are not covered by the available rules in the ASME code. The analysis engineer will be one of our registered Professional Engineers with extensive knowledge and relevant experience in pressure vessel design and FEA usage, and is qualified to complete, certify and sign off on the analysis results.

A complete FEA report of the pressure vessel design will be presented once the analysis is complete as proof of Code compliance. The FEA report will contain an executive summary, briefly describing how FEA was used to support the design, the FEA model developed, the results of the FEA, and conclusions relating to the FEA results supporting the design submitted for registration.

The introduction of FEA report will describe the scope of the FEA analysis relating to the design, the justification for using FEA to support the design calculations, the ANSYS FEA software used for the analysis, and the type of FEA analysis (i.e. static, dynamic, elastic, plastic, small deformations, large deformations, etc.)

The main section of the FEA report is to completely describe the FEA model used for the analysis, including the description of dimensional information and/or drawings relating the model geometry to the actual pressure vessel geometry, explanation for simplification of geometry, if any, to justify it as appropriate, the description of the element mesh and type (h, p, 2D, 3D), shape, and order (2nd order or above), and how the different elements were connected together if different types of elements are used. When using shell elements, the top or bottom orientation with plots of the elements, and whether thick or thin elements are used will also be described in this section.

In addition, the turn angle of each element used on the inside fillet radii, how the size of mesh elements were chosen with reference to global or local (bias) mesh refinement , and in what manner the two separate flange faces are linked (e.g. contact elements) will also be described in the report.

Boundary conditions such as supports, restraints, loads, and forces will be clearly described and shown (as figures) in the report. When partial models are used (typically based on symmetry), the rationale for the partial model will be explained with a description of the boundary conditions used to compensate for the missing model sections.

The accuracy of the model digitization will be indicated, either by the described use of convergence studies or by comparison to the accuracy of previous successful in-house models. This section of the report will also include a proposed method to verify that the model results reflect the real response of the physical pressure vessel.

The relevant result and figures, including displacement plot, deformed shape with un-deformed shape superimposed, stress plot with mesh showing discrete color separation for stress ranges, comparison between the size of stress concentrations and the size of the mesh, plot with element stress, comparison of nodal (average) stress vs. element (non-averaged) stress (if the small difference is less than 5%, the accuracy is acceptable), and comparison of reaction forces with applied loads, will be presented in the report with discussions relating to each and every figure to explain what is the purpose of the figure and why it is of importance.

The overall model results and areas of interest will be analyzed, and are related to the defined allowable stresses of the Code of construction using the appropriate ASME methodology.

In short, CCPGE will provide highly-qualified FEA fatigue stress analysis reports for verifying the pressure vessel design.

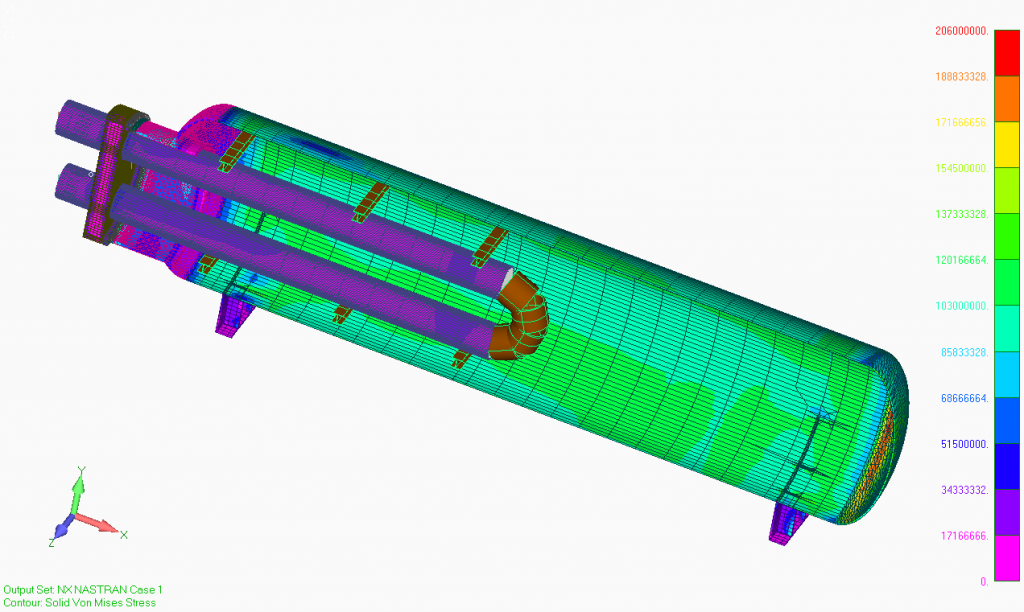

Von Mises Stress Distribution of a Non-Standard Sour Separator Vessel

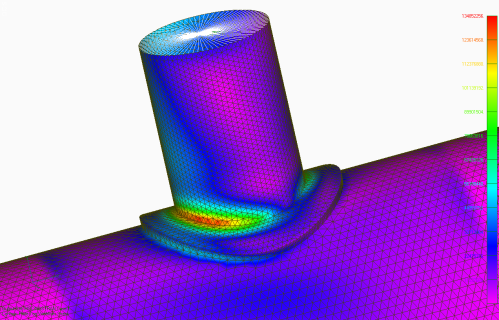

Concentrated Stress Distribution at the Inlet Nozzle of a Compressor Suction Bottle

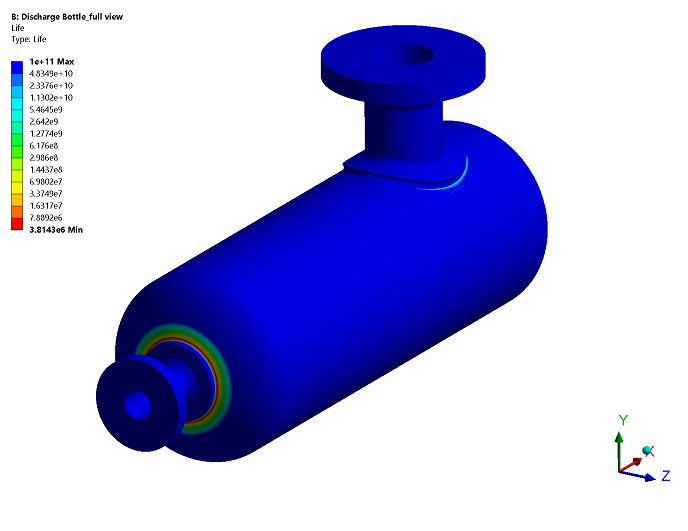

FEA Calculated Fatigue Life of a Compressor Discharge Bottle

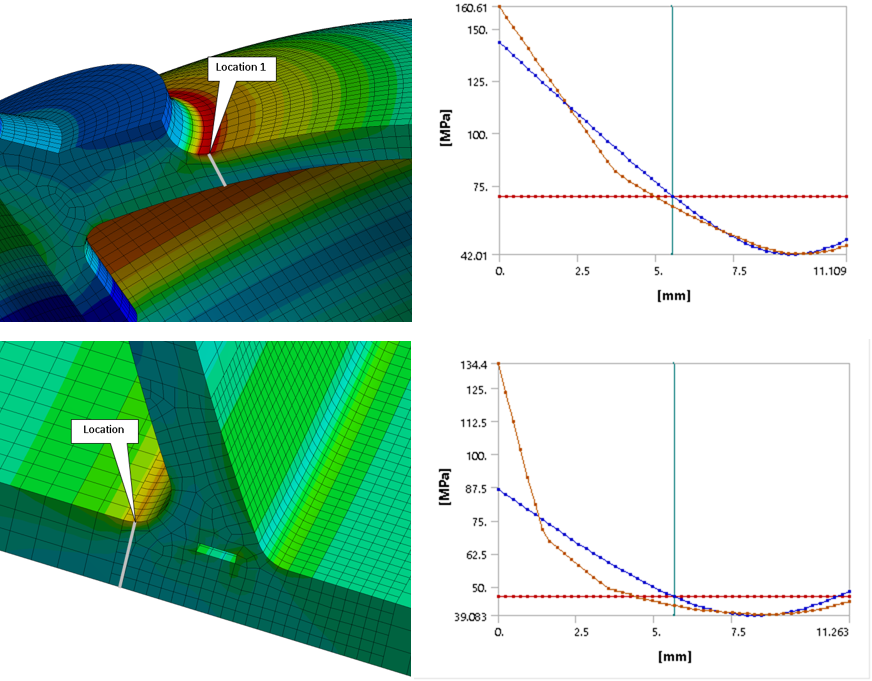

Stress Classification Lines and Linearization Results

![[PNG] _ccpge-logo-wide-black](http://www.ccpge.com/wp-content/uploads/2023/09/PNG-_ccpge-logo-wide-black.png)